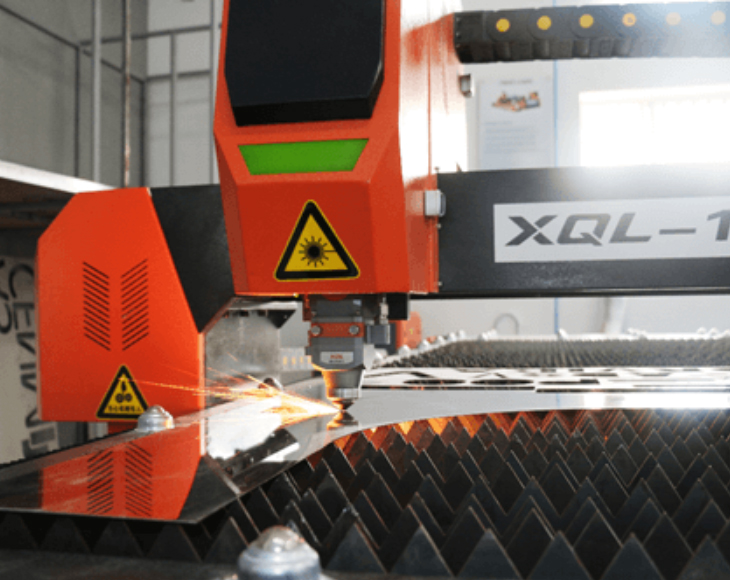

Metal-Laser Cutting Machines

◉ Smaller focusing spot, increased efficiency, and superior cutting quality characterise excellent beam quality.

◉ High cutting speed: twice as fast as competing CO2 laser cutting devices of comparable power.

◉ High stability: The machine's main parts have a 100,000-hour lifespan and are made of a top-notch fibre laser that was imported from throughout the world.

◉ High electro-optic conversion efficiency: three times more effective than typical CO2 lasers while using less energy.

◉ Low operating costs: The total energy usage is only 20% to 30% of that of a conventional CO2 laser cutting machine.

◉ Intelligent operation and simple maintenance: thanks to fibre optic transmission, there is no need to modify the optical path.

◉ Stainless steel, carbon steel, silicon steel, titanium alloy, galvanised, and other metallic sheets are applicable materials.

Acrylic Laser Cutting Machines

APPLICATION VERSATILITY

◉ Smaller focusing spot, increased efficiency, and superior cutting quality characterise excellent beam quality.

◉ High cutting speed: twice as fast as competing CO2 laser cutting devices of comparable power.

◉ High stability: The machine's main parts have a 100,000-hour lifespan and are made of a top-notch fibre laser that was imported from throughout the world.

◉ High electro-optic conversion efficiency: three times more effective than typical CO2 lasers while using less energy.

◉ Low operating costs: The total energy usage is only 20% to 30% of that of a conventional CO2 laser cutting machine.

◉ Intelligent operation and simple maintenance: thanks to fibre optic transmission, there is no need to modify the optical path.

◉ Stainless steel, carbon steel, silicon steel, titanium alloy, galvanised, and other metallic sheets are applicable materials.

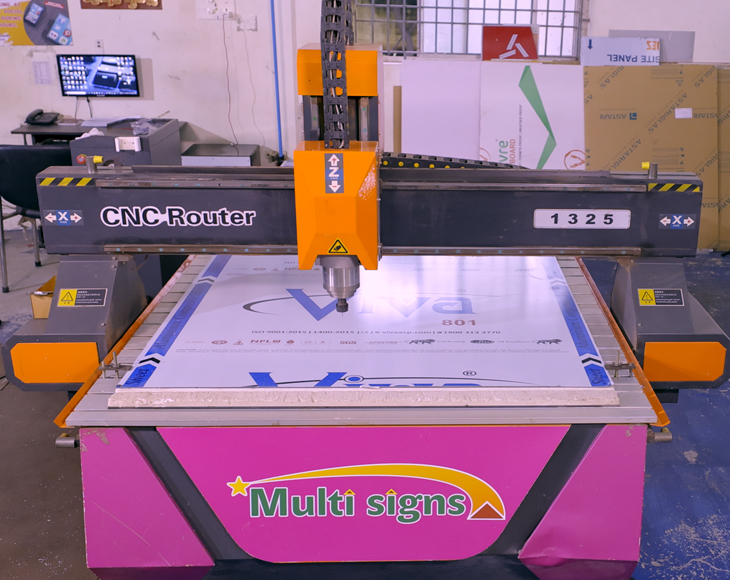

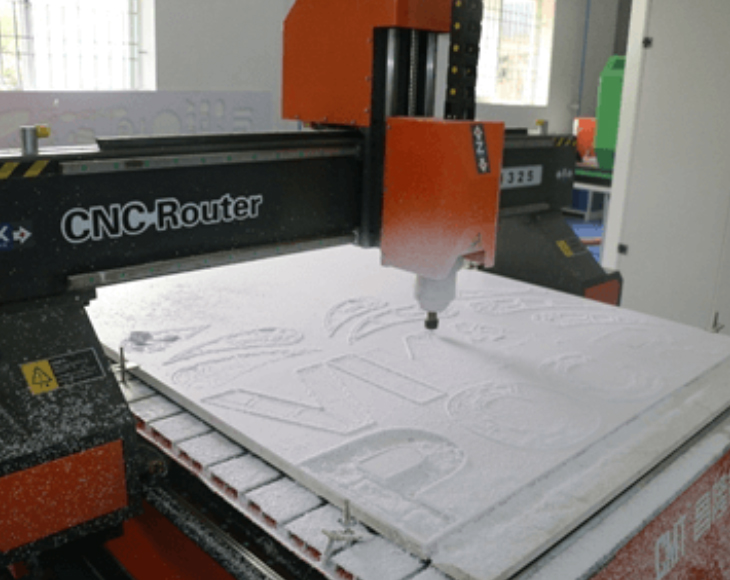

CNC ROUTERS

APPLICATION VERSATILITY

◉ High rate of cutting

◉ High stability: imported fibre laser technology

◉ Smart operation and simple maintenance: fibre optic transmission eliminates the need to modify the optical line.

◉ Acrylic, wood, cardboard, plastic, sun board, and glass are materials that can be used.

ALUMINIUM - BENDING MACHINE VIEW LARGER

APPLICATION VERSATILITY

◉ Quality Bends: Our aluminium bending machines are designed to produce exact bends in materials made of aluminium.

◉ Faster and more efficient production is made possible by aluminium bending machines, which streamline the bending process.

◉ Flexibility: To meet the needs of various projects, our machines are made to handle a variety of aluminium profiles and sheet thicknesses.

◉ High-Quality Bends: Our aluminium bending equipment produces bends with clean edges and few surface flaws.

◉ Ease of Use: Our aluminium bending machines include straightforward controls and user-friendly interfaces, making them simple to use.

SS - BENDING MACHINE

APPLICATION VERSATILITY

◉ Bending machines, also known as press brakes, are used to bend sheet metal and other materials.

◉ They are commonly used in metal fabrication for industries such as automotive, aerospace, construction, and manufacturing.

◉ Bending machines apply force between a punch and die to deform the material into a desired shape or angle.

◉ Types of bending machines include mechanical, hydraulic, servo-electric, and CNC press brakes.

◉ CNC press brakes are automated and offer precise and repeatable bending.

◉ The bending process involves material preparation, setup, loading, bending, and unloading.

◉ Bending machines can be operated manually, semi-automatically, or fully automatically.

◉ They are equipped with safety features and can be used with other sheet metal processing machines.

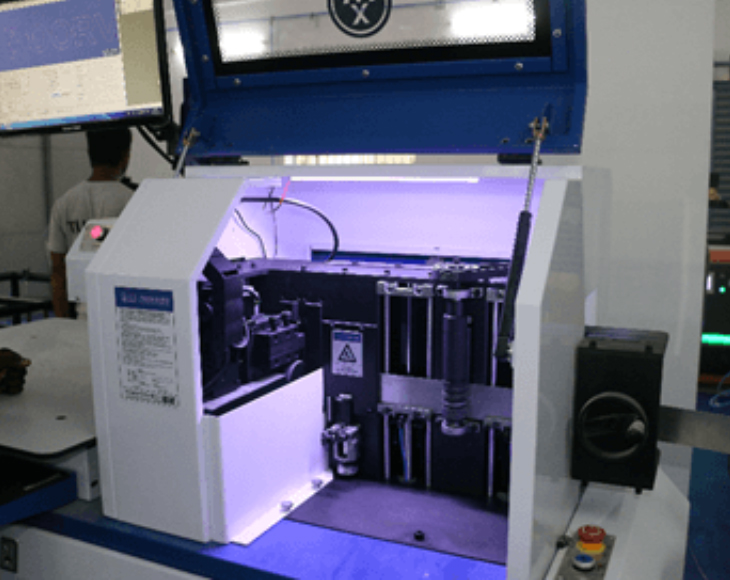

UV MACHINE

APPLICATION VERSATILITY

Driving Sys

High quality conveyor belt with sectional vacuum suction, which keeps the flexible and rigid materials stay firmly on platform to prevent media inclining or wrinkle.

LED Curing

Using LED UV curing system for power saving purpose, and less heat on media which is applicable to many a materials

Loop Control

Loop controlled media feeding and take-up system makes more stable and efficient materials feeding and collecting.

Printheads

Powered by state of-the-art P.H. for mass production capability, with print speed of 180sqm at production mode, and up to 260sqm at draft printing mode.

Maglev Tech

Equipped with Maglev driving system and metal encoder raster at X axis to achieve reilable and smooth movement and accurate placement of ink drops with super printing speed 30% ink consumption saved compared with old technologies.

HP-3200 Latex Printer

HP-570 Latex Printer

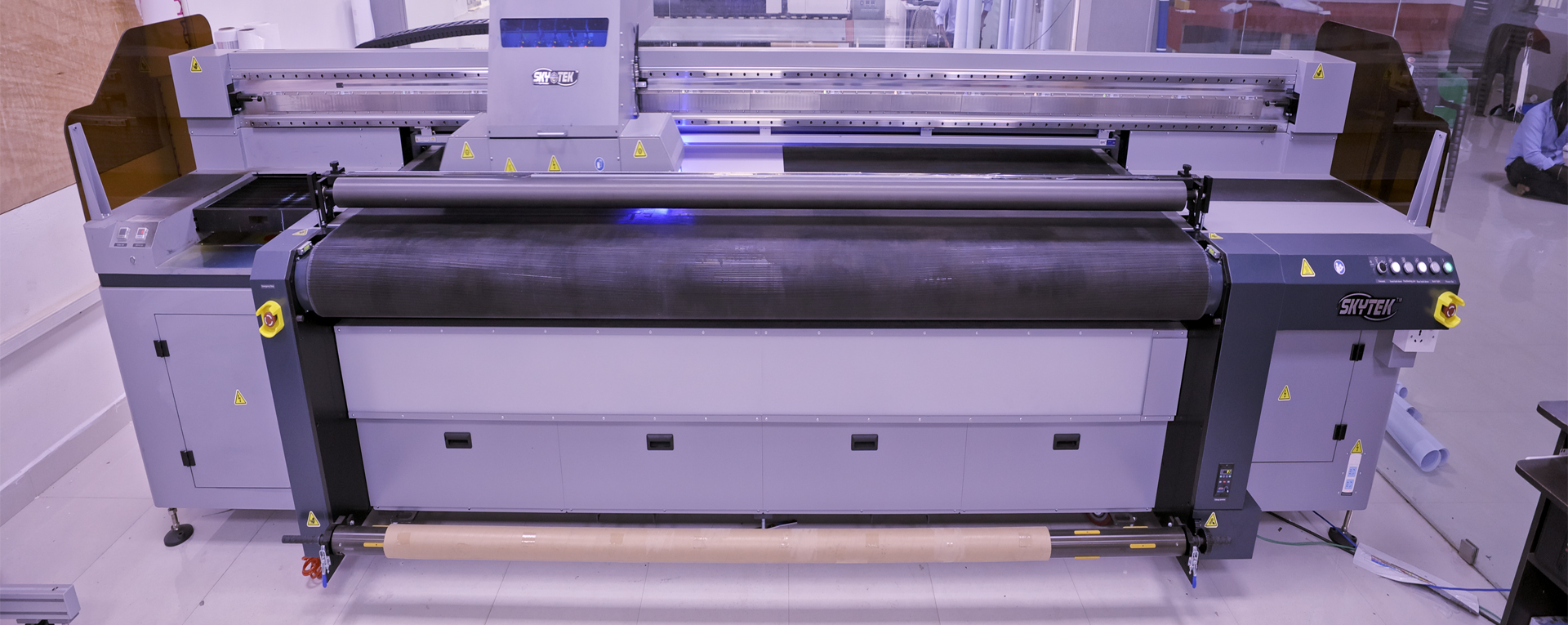

Skytek Hybrid 3200 UV Printer

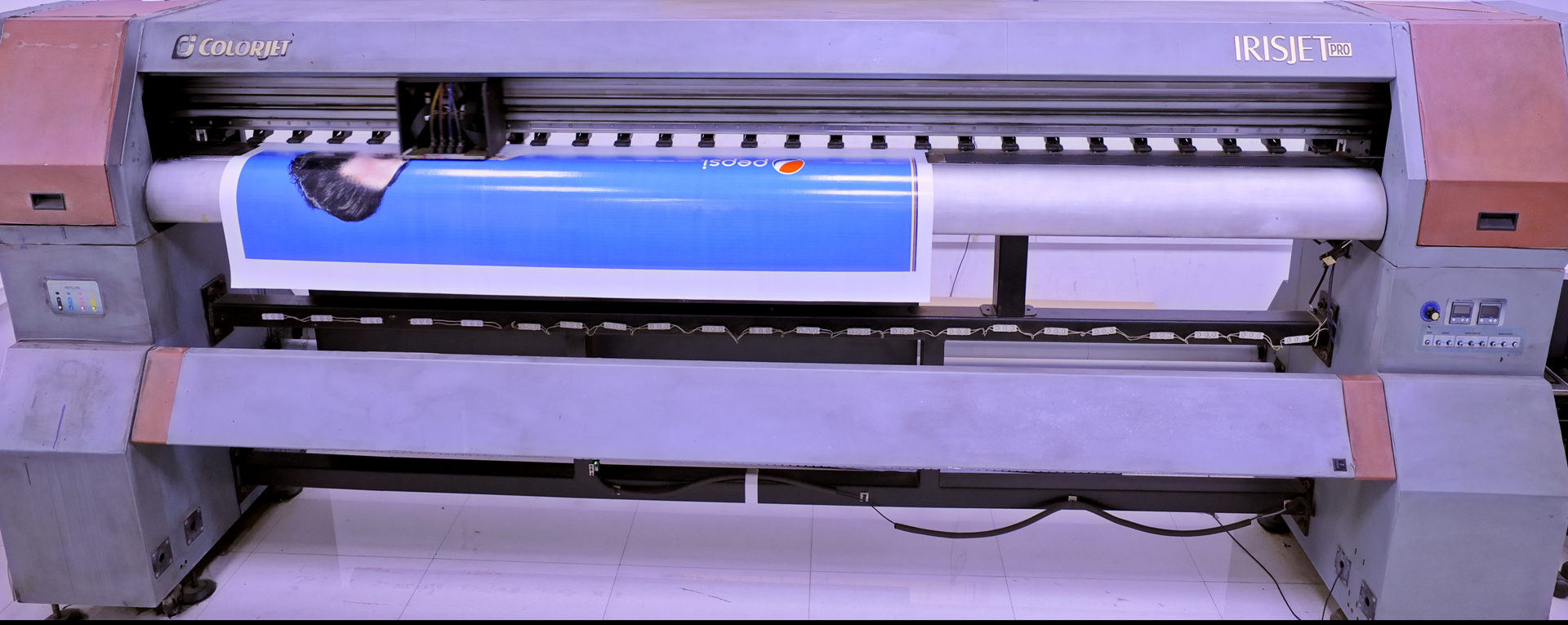

Colorjet-Solvent Printer

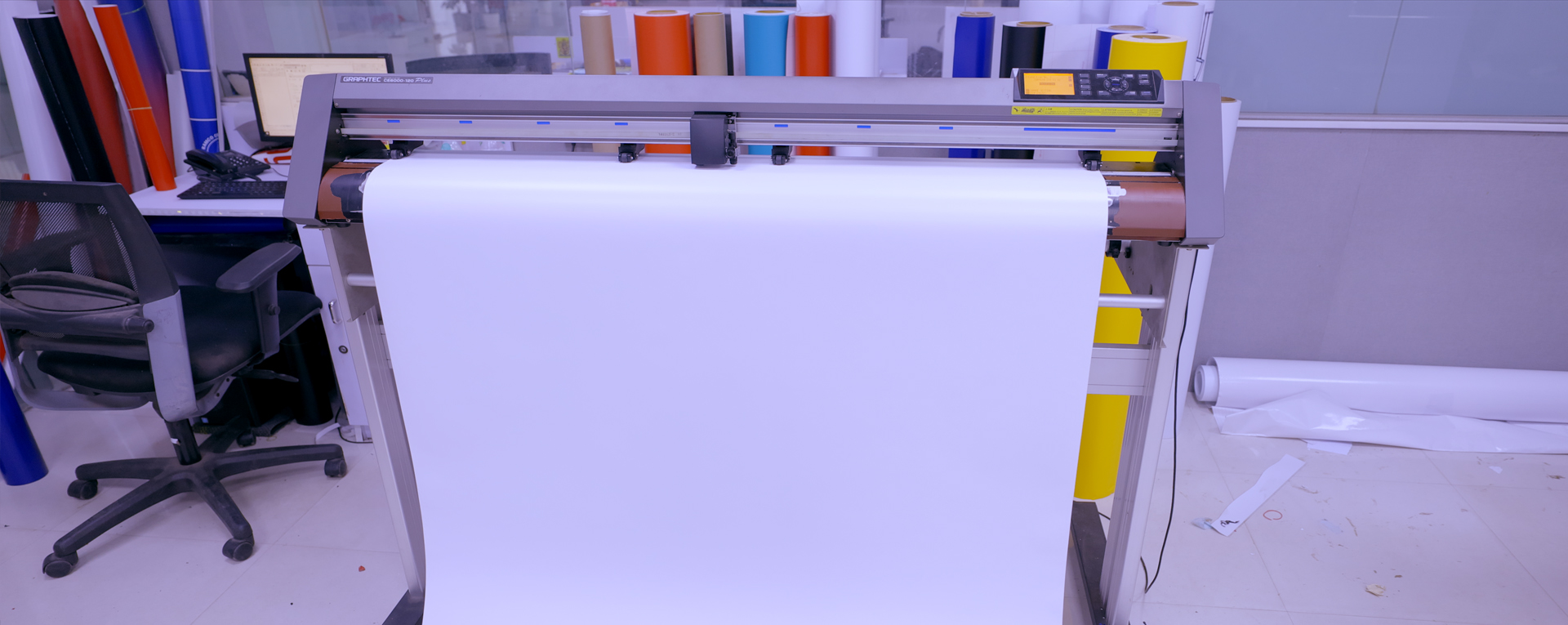

CE6000-Graphtec Plotter

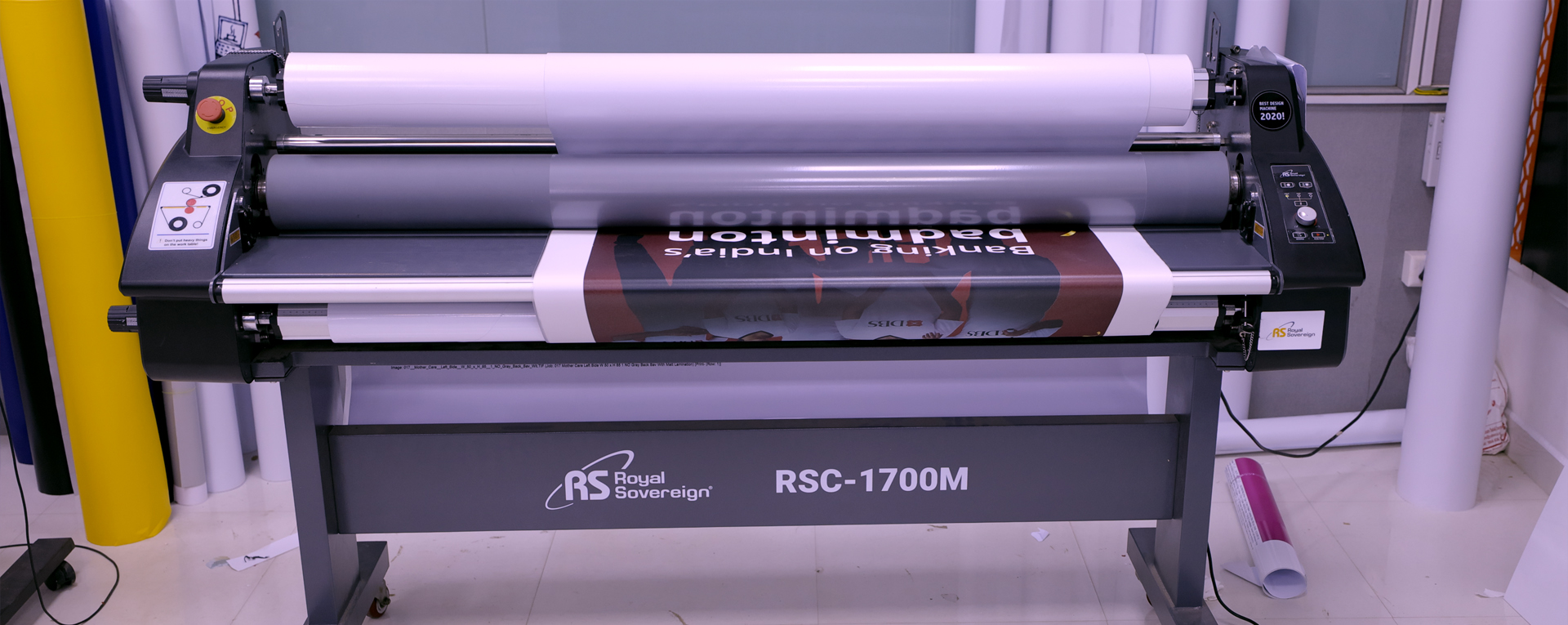

RSC-1700M Laminator